Cooking ends up generating a lot of dirt and waste, especially liquid waste. This buildup of waste, if left unchecked, not only becomes gross but can also be a serious and expensive process to undo.

For example, it can create issues at local water treatment facilities and clog sewer system in the neighborhood. As such, it's a really bad idea and unnecessary to pour FOG (fats, oils, and grease) down the drains and affect everyone's sewer system.

While it’s a simple process to get rid of FOG at homes by just pouring it into a can or jar that's empty, it becomes a rather daunting task for larger-scale establishments. This is where a grease trap/grease inceptor comes in handy.

What is a Grease Trap?

Grease traps or grease inceptors have been in use since Victorian times, with the first patent for a modern-day grease trap issued to Nathaniel Whiting in the late 1800s.

Grease traps vary in size, with smaller variations designed to connect individual sinks and larger ones installed to service larger facilities.

The definition of a grease trap is "a trap in a drain or waste pipe to prevent grease from passing into a sanitary sewer lines and system."

A grease trap/grease inceptor is in simple terms a plumbing fixture that contains decomposing food waste, bettering the sewer system.

There are three main types of grease traps:

- Passive hydromechanical, also known as manual

- Automatic grease traps, or automatic grease removal units

- Gravity grease traps

Each type of grease trap can be used for different reasons. Read about their differences here.%2C%20automatic%20and%20gravity.)

What is The Purpose of a Grease Trap/Grease Inceptor?

The wastes in food solids, even oils and grease, generated by large establishments such as schools, cafeterias, and restaurants is significantly more in both frequency and volume. If left unchecked, the food solids could end up accumulating in sewer pipes and create sewer system problems such as:

-Foul Odors

-Blocked drainpipes and sewers

-Restricted flowing rate of wastewater

To prevent these problems from arising it becomes necessary to get specialized devices installed. The device in question is called a grease interceptor or a grease trap (these terms are used interchangeably).

Health inspectors typically ensure that large establishments have grease traps (or grease inceptors) installed on their premises.

How Does A Grease Trap Work?

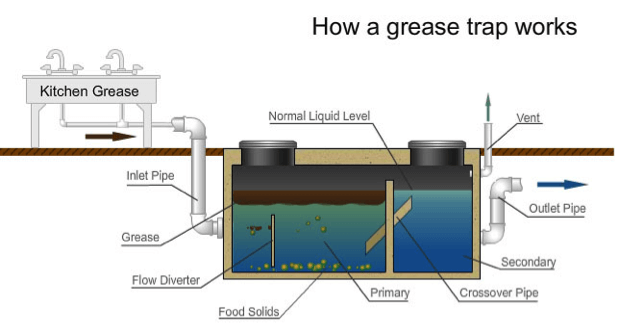

In the most fundamental term, a grease trap or grease inceptor functions by cooling warm or hot greasy water. By allowing the fat, grease and oil (FOG) to cool, a grease trap is able to separate the different layers of wastes with water.

FOG are lighter in density and float at the surface of the tanks, and the cooled water – minus the FOG - continues draining to the sewer system.

FOG float to the top of the water are then trapped by the grease trap. For its use to be effective, the grease trap/grease inceptor should be emptied when the sludge level reaches 25% of the tank level.

The larger “gravity” or “passive” traps rely more on gravity and time to separate FOG. Standpipes, internal baffling, and larger tank sizes allow the magic of gravity to work by increasing the “retention time” on these passive grease traps/grease inceptors. The services of a professional should often be sought at intervals.

For smaller, indoor types a hydro-mechanical grease interceptor should be used instead. The traps used in the interceptor utilize internal baffles that provide more space and time for separation by lengthening the circulation path and maximizing the flowing rate.

In order to maximize separation of FOG from effluents, the wastewater making its way inside the grease trap should be regulated by control devices that at this stage also allow mixing of air.

Grease Trap or Interceptor Sizing

The size of a grease trap is, needless to say, the most important thing for an establishment to consider. This is tied to the rating that hydro-mechanical interceptors have in terms of the allowable maximum drainage in gallons per minute (GPM). Naturally, hydro-mechanical receptors have a 100gpm handling capacity, and anything beyond this should be left to the gravity receptor.

Things that influence the grease trap/interceptor sizing are:

-Sizing as per Values of Drain Fixture Unit (DFU)

-Sizing as per the volume of total flowing fixtures

-Sizing based on waste pipe’s diameter

To this end, it becomes necessary to have a manufacturer that provides charts with GPM flowing listing based on the diameter of the pipe.

Provided you know the waste pipe's size and type of the grease trap/grease interceptor, this method becomes very simple. Similarly, using DFU values for sizing is straightforward because one only has to sum up the DFU values for the waste flowing into the grease trap.

Some basic math is required when calculating the grease interceptors' size based on the flow and capacity of the actual waste.

First, you’ll need to determine the fixture’s dimensions, which will, in turn, determine the fixture’s volume in cubic inches.

Secondly, that figure would need to be converted to gallons. To better illustrate this, divide the volume aforementioned (cubic inches) by 231 to find the number of gallons of waste.

Thirdly, multiply the figure resulting from above by 75%. This is because it is very unlikely that the fixture will fill to the brim even on busy occasions.

Finally, calculate the flowing/draining rate.

So how is a flowing rate calculated?

You’d need to fill the fixture with water to 75% capacity, which is 3/4 of the total fixture. Next, time the length of the period it takes for the fixture to clear out completely.

Lastly, take the result you had in the third step above and divide it by the time it takes for the fixture to come out. The result you get is now the rate in GPM.

At this stage, it would be advisable to seek the guidance of a professional or a manufacturer. Also, depending on the local laws, you may need to consult the local health and hygiene department to be sure that the grease trap you have fits your needs as, let's say, with owning restaurant kitchens.

If a grease trap is too large, and you run the risk of damaging things downstream as sulfuric acid may be created within the tank.

If grease traps are too small, and the unit will not do its purpose of preventing FOG from passing through freely unless it’s periodically cleaned.

Furthermore, the Code of Uniform Plumbing that acts as a guideline in this space prescribes that unless specifically required by the jurisdiction’s authority, dishwashers are not to be attached to a grease trap.

This is because chemicals and other detergents used can emulsify the FOG rendering the grease trap/grease inceptor unusable.

Again, the Code only permits garbage disposals to flow unhampered into drainage systems, affecting plumbing. It goes without saying that it is imperative to check with the local authority before purchasing or getting down with the sizing process of grease traps.

What Could Possibly Go Wrong With Grease Traps?

If the trapped FOG is not pumped out when needed, it becomes thick and may begin to escape via the outlet tee.

Also, when blocking occurs in the downstream pipes, the grease traps/grease inceptors and drains containing the wastewater could flood out.

This could consequently lead to your commercial kitchen and business being shut down by local sanitary officials for wastewater plumbing system damage. Grease traps/grease inceptors are a way to prevent this.

How Often Should You Pump Your Grease Interceptor?

For the correct functioning of grease traps/grease inceptors, a deep layer of water is needed. To this end, it's recommended that a grease trap be drained as soon as the food layers and grease occupy 25% of the trap’s space.

Pumping is dependent on:

1) Grease trap cleaning practices

To reduce the amount of FOG going down the drain, it's necessary that you have good grease trap cleaning practices in place. Dishes should be scraped before being washed. As a result, less food and grease (FOG) will make its way down the drain. Again, as a standard practice, high-fat liquids and fryer oils should never be allowed to flow down the drains, even with water, or else the need for grease recovery increases.

2) The type of food

The more grease in the waste, the more often it needs to be pumped. Waste in the form of frostings, sauces, meats, salad dressing, and butter oils means a higher frequency.

3) The amount of food

Busy establishments lead to more waste products being washed down the drains. For this reason, busy seasons mean a higher pump frequency. Needless to say, busy season isn't a convenient time for having your business and commercial kitchen flooded.

4) The trap or interceptor sizing

It goes without saying that the smaller the grease traps/grease inceptors are, the more often it will need to be pumped.

Is Anything Else Needed for an Effective Grease Trap?

If the grease interceptor is not drained often enough, the inlet and outlet often become clogged with fats, oils and grease (FOG). For this reason, the drainage should be cleaned at a higher frequency.

Furthermore, other drains in your establishment also require some maintenance in terms of periodical cleaning. The frequency depends on the amount of “fall” in the sewer lines, on usage, and other conditions. For best practice, have the sewer lines cleaned at least once a year, and more often if the need arises.

Common Guidelines for Your Restaurant Kitchen Business & Other Commercial Kitchen

To mitigate issues associated with foul odors from blocked drains and sewer system issues, officials from the local health and hygiene department recommend the following tips:

-Using quick breaking biological additives and detergents for boosting the operation of the system

-Using grease traps/grease inceptors service providers for periodical grease trap washing (if you're located in North Carolina, we can help you with that!)

-Minimizing the amount of grease, oils, and solids entering the grease traps/grease inceptors

-Minimizing wastewater temperature to enhance the functionality of grease traps. The lower the temperatures of the waste, the better.

-Ensuring that wastewater volumes and flowing rates correspond to the grease trap’s design capacity

-Installing sufficient pre-treatment devices that reduce the contaminant levels in wastewater from a scullery, commercial kitchen, etc.

-Avoiding the use of running water for thawing frozen food

-By ensuring that dishwaters are only used in cases where there’s a full load

-Reducing wastage by turning off taps when not in use/when water isn't needed

-Setting waste cooking oils aside for recycling rather than disposing of it

-Scraping food from plates and dishes before washing them

-Identifying and understanding the input sources to the wastewater stream

A well-maintained grease trap/grease inceptor will give you years of service. Even more importantly, it'll also prevent health and hygiene-related issues, especially when the inspectors from the local jurisdiction come calling.

Properly maintaining your grease trap is essential. Now that you know how a grease trap works, make sure you contact a local grease trap cleaning business or provider to set up a regular maintenance schedule.

At Grease Cycle, we want you to focus on your business instead of dealing with a grease trap that is backing up! Our business is here for you! Hire our services today!